Micro-motion transducer for use in a reverse shoulder arthroplasty prosthetic

Developed and tested a sensing element that can detect and measure (in vitro) the micro-deflections between the glenospheric prosthetic baseplate of a reverse shoulder arthroplasty and the scapula bone in a single degree of freedom.

Measured deflections between 10-300 μm 0μm with a sensitivity of 5 μm.

Designed so that the stiffness of the overall system is 10 times less than the stiffness of the construct providing a factor of safety to prevent restriction of the relative movement of the measured components.

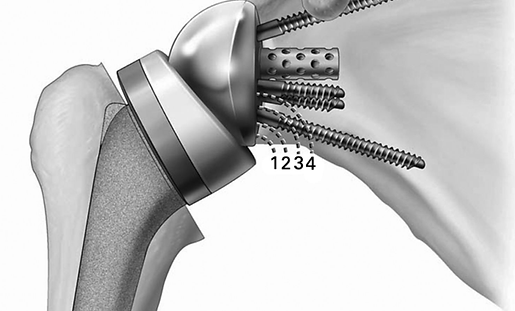

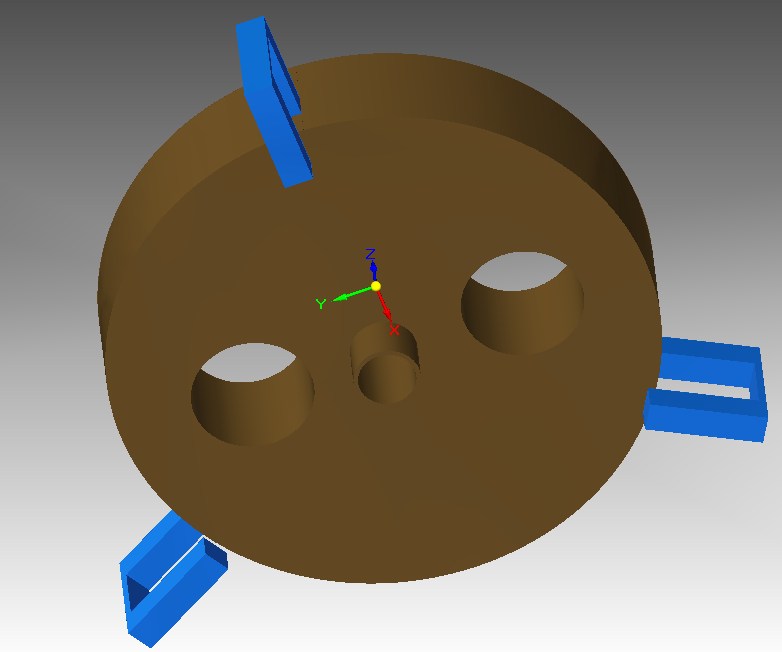

Measurements of the actual an baseplate for the reverse shoulder prosthetic. This is used for preliminary arrangement of micro-motion transducers.

Arrangement of micro-motion transducers for measurement of the prosthetic around about the baseplate.

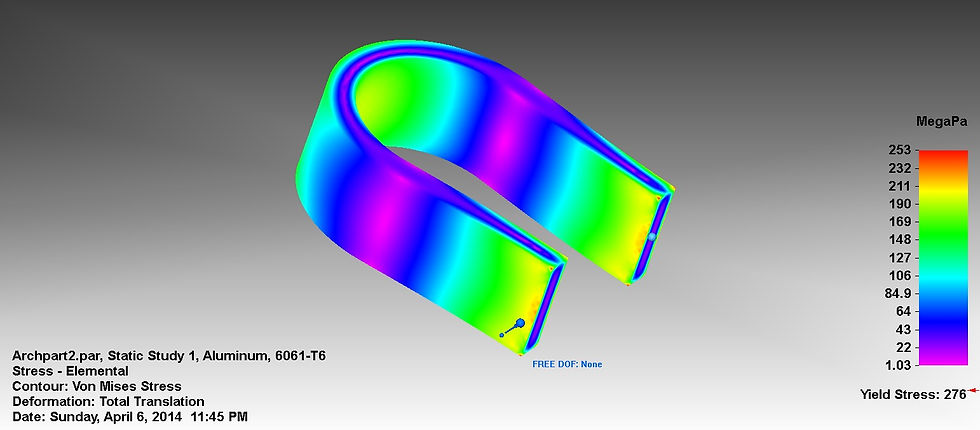

Preliminary square shaped design is converted into an arch shaped design to alleviate non-linear stress concentration measurements. This ultimately increased the measurement capabilities of the transducer.

Simulation of Von Mises Stresses within the transducer under the max compression scenario.