3D Printed Gearbox Design

Designed a gearbox for the task of lifting a 15 kg weight using an 12V DC electrical motor.

Employed theoretical and emprical approaches to make gearbox assembly.

Analyzed static failure and fatigue failure theories to provide design limitations and analysis theory of gears and shafts.

Created four components in total using CAD software (SolidEdge) including gears, shafts, housing and bearings.

Determined the gear ratio, number of teeth, basic shaft layout and size of bushings to be ordered.

Redesigned the gears and shaft for prototyping, modifying the original steel design so that it can be printed in plastic.

Placed 4th fastest (out of 15 gearboxes) in gearbox lifting competition.

CAD model of exploded gearbox assembly view showing all individual printed parts.

CAD model of fitted gearbox and dimensions.

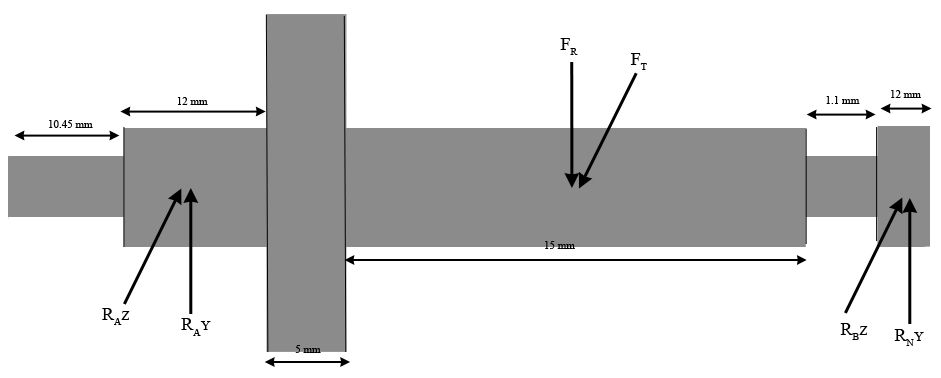

Free Body Diagram of the gear shaft. Used for static and dynamic calculations.