Contact lens mold design and milling

Designed and manufactured of a set of contact lens molds, both convex and concave mating faces using a Sherline Mill 2010 and aluminum 6061.

Evaluation criteria in design included minimizing the cost of the materials and machining, applying careful machining practices and maintenance, optimizing machining time with tool and/or workpiece capabilities, achieving precise and accurate geometric mold structures and minimizing surface roughness.

Utilized Solid Edge, Mastercam and two flat endmill tools (1/4 inch and 1 mm diameter).

Post machined convex mold shown left, and smoothed using aluminum oxide powder

Concave mold before (left) and after smoothing (right). Smoothed using aluminum oxide powder.

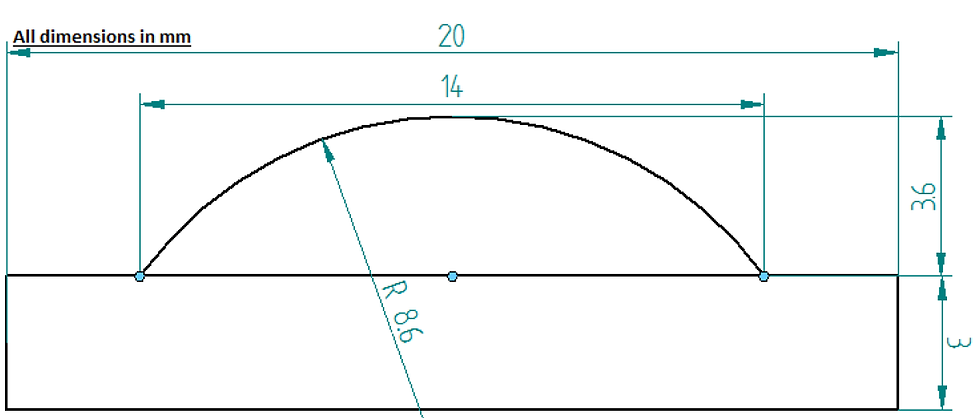

Side view drawing of contact lens convex mold

Step 1/3 Concave Mold

Step 2/3 Concave Mold

Step 3/3 Concave mold

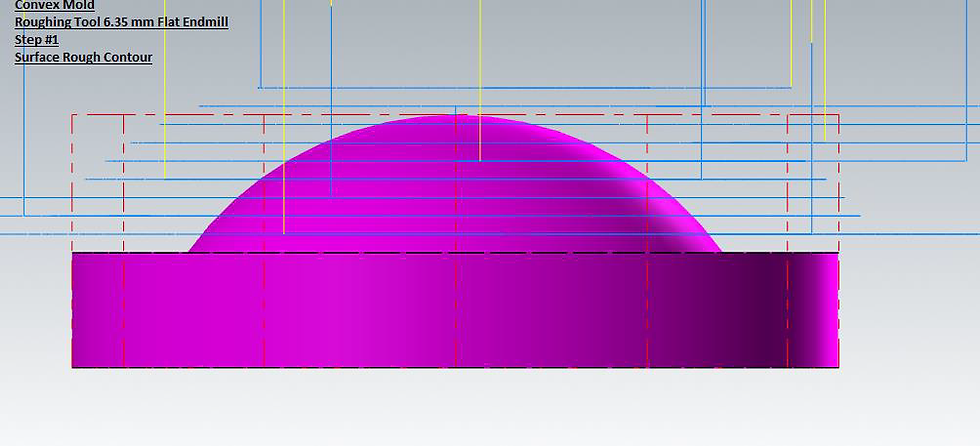

Step 1/3 Convex Mold

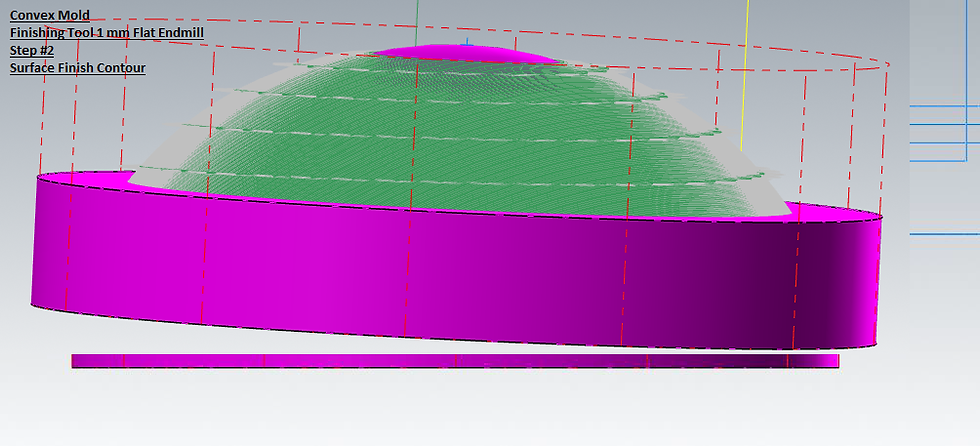

Step 2/3

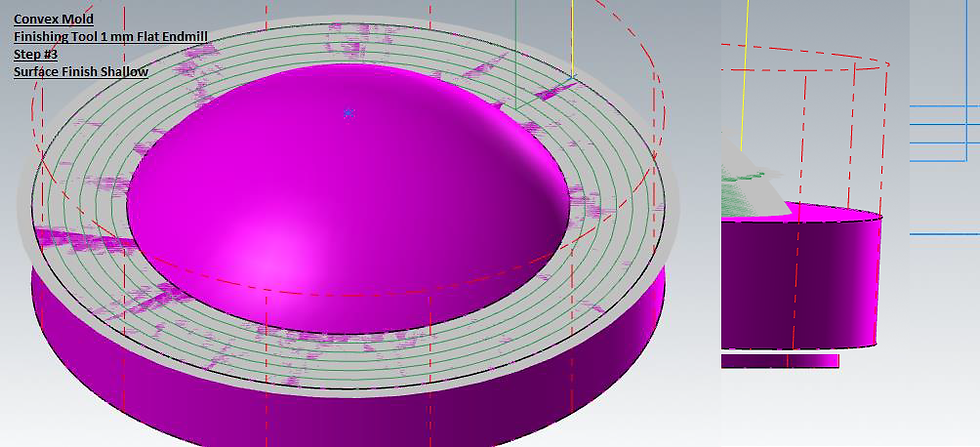

Step 3/3